Fouling

Fouling for any boat, large or small eats boatspeed, fuel and satisfaction. Most boats haul out every year, pressure wash off or scrape off the marine flora and fauna that have taken up residence. Owners then repaint the hull with a toxic antifouling paint. Toxic to marine life, and unpleasant to human. In small boats the toxicity has been greatly reduced over the years, some would argue so has the effectiveness. The problem is the paint erodes and the toxins leak. High concentrations of boats lead to high concentrations of toxins.

For larger ships the cost of antifouling is significant. Interruption to service and the cost of a period in dry dock. Antifouling on large ships is considerably more toxic than available for the pleasure boat industry to extend the periods between maintenance to several years.

About 10 years ago I coated my boat with copper particles embedded in epoxy. The exposed copper surface of the particles reacts with sea water to create a non soluble copper compound. This doesn’t leach, but like clipper ships coated in solid copper sheets discourages marine fouling. I have not painted since. Until a few years ago I did need to scrub off. I would see a few barnacles and some marine growth, but no more than would be normal with toxic paint.

A few years ago I added 2 ultrasonic antifouling units. These send low power ultrasonic pulses into the hull and the water. According to research performed at Singapore University, barnacle larvae use antennae to feel the surface they are about to attach to. Once attached the antenna stick to the surface and convert into the shell. Once attached, they never fall off. Ultrasound at various frequencies excites the antenna which disrupts the sensing process. The larvae swim past to attach elsewhere. There is also some evidence that ultrasound reduces algae growth. The phenomena was first discovered testing submarine sonar over 50 years ago. My uncle did submarine research in various scottish locks during the war.

The ultrasonic antifouling I have fitted currently was a punt. 2 low cost units from Jaycar, first published in an Australian electronics magazine, that you put together yourself. Those are driven by a 8 pin PIC driving 2 MOSFETS. I think it’s made a difference. After a year in the water I have no barnacles and a bit of soft slime. There are expensive commercial units available at more cost, but the companies selling them seem to come and go. I am not convinced enough to spend that sort of money but I am curious and prepared to design and build a unit.

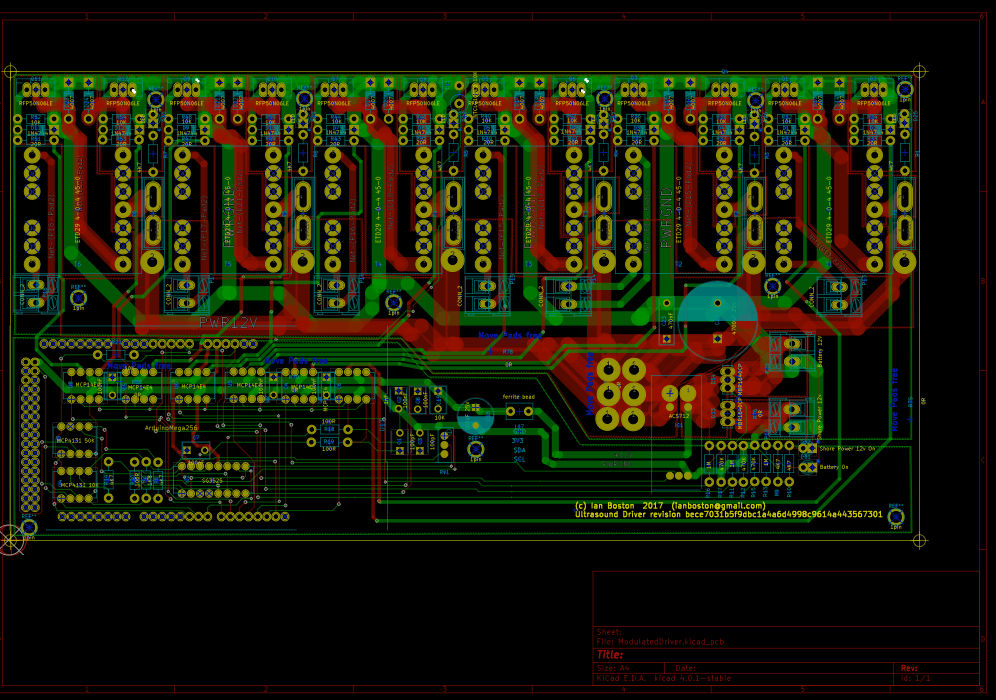

The new unit (board above), for the new boat is a bit more sophisticated. Its a 6 channel unit controlled by an Arduino Mega with custom code, controlling a MOSFET signal generator and 6 pairs of MOSFETS. It outputs 15-150Khz at up to 60W per channel. A prototype on the bench works and has my kids running out the house (they can hear the harmonics). My ears are a little older so can’t, but still ring a bit. I won’t run it at those levels as that will likely cavitate the water and kill things as well as eat power. It remains to be seen if the production board works, I have just ordered a batch of 5 from an offshore fabrication shop.